Sodiceram represents a powerful blend of craftsmanship, technology, and forward-thinking strategy within the global ceramic industry. Known for its commitment to quality manufacturing and refined design standards, the brand has steadily carved a respected position in international markets. This article explores its origins, operational strengths, sustainability framework, market presence, and future outlook while maintaining a clear focus on innovation and customer-centric development.

The ceramic industry has undergone remarkable transformation over the past few decades. Advancements in production techniques, digital printing technology, environmental regulations, and global trade dynamics have reshaped how manufacturers operate. Within this evolving landscape, this company has demonstrated adaptability, resilience, and strategic vision that continue to define its reputation.

The Origins and Vision of Sodiceram

The story of Sodiceram begins with a clear mission: to combine traditional ceramic craftsmanship with modern industrial efficiency. From its earliest days, the company positioned itself as a manufacturer focused not only on production capacity but also on product reliability and aesthetic distinction. Its foundational vision centered on three guiding pillars: quality, innovation, and sustainable growth.

In its formative years, the organization invested heavily in research and development. Rather than relying solely on conventional manufacturing practices, it embraced advanced kiln technology, precision glazing systems, and automated inspection processes. This early adoption of technological upgrades allowed the business to achieve consistent product standards while maintaining competitive pricing. The ceramic industry often measures success through durability, surface finish consistency, dimensional precision, and design appeal. By integrating these elements into its operational blueprint, the company built a foundation for long-term scalability. The leadership recognized that global competitiveness required more than volume; it required reliability and brand trust.

The table below illustrates a simplified comparison of key ceramic production performance indicators that influence market competitiveness.

| Performance Indicator | Industry Standard Average | High-Performance Benchmark |

|---|---|---|

| Water Absorption Rate | 0.5% – 3% | Below 0.5% |

| Dimensional Accuracy | ±1.5 mm | ±0.5 mm |

| Surface Finish Consistency | Moderate Variation | Minimal Variation |

| Breakage Rate | 5% | Below 2% |

By aligning production standards closer to high-performance benchmarks, the company strengthened its reputation for reliability in both domestic and export markets.

Manufacturing Excellence at Sodiceram

Manufacturing excellence stands at the core of Sodiceram’s operational identity. The production process integrates raw material selection, milling precision, spray drying consistency, pressing accuracy, glazing application, and high-temperature firing cycles. Each stage is carefully monitored to reduce defects and ensure uniform output.

Raw material sourcing plays a critical role in ceramic durability. Clay composition, mineral content, and impurity levels directly affect the final product’s mechanical strength and aesthetic finish. The company maintains strict procurement standards to guarantee consistency in supply quality. Energy efficiency has also become a major focus in modern ceramic manufacturing. Kiln operations consume significant energy, and optimization directly influences production costs and environmental impact. Through the adoption of advanced firing systems and heat recovery mechanisms, the organization has enhanced thermal efficiency while lowering emissions.

A breakdown of the production workflow highlights the structured approach followed in modern ceramic plants.

| Production Stage | Primary Objective | Quality Control Focus |

|---|---|---|

| Raw Material Mixing | Homogeneous composition | Particle size uniformity |

| Spray Drying | Controlled moisture content | Granule consistency |

| Pressing | Uniform density formation | Dimensional stability |

| Glazing | Surface protection and aesthetics | Coating thickness accuracy |

| Firing | Strength and durability enhancement | Temperature cycle precision |

This systematic approach ensures minimal variation between batches and strengthens supply chain reliability.

Design Philosophy Behind Sodiceram Collections

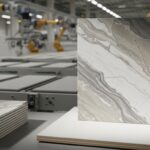

The design philosophy behind Sodiceram collections reflects a balance between contemporary trends and timeless aesthetics. Modern architectural spaces demand versatility, durability, and visual harmony. To meet these expectations, the brand integrates digital design tools with market research insights.

Interior designers increasingly seek ceramic solutions that replicate natural textures such as marble, stone, wood, and concrete. Advanced digital printing technology enables high-resolution surface detailing that closely mimics these materials. The result is a product that delivers visual authenticity without compromising durability. Color psychology also influences design decisions. Neutral tones often dominate commercial environments, while residential spaces may incorporate warmer or textured finishes. The company adapts its collections based on regional preferences, climate conditions, and architectural patterns.

Large-format tiles have gained prominence due to their seamless appearance and reduced grout visibility. By expanding production capabilities to accommodate larger dimensions, the manufacturer has aligned itself with global architectural shifts. Beyond aesthetics, safety and performance remain critical. Slip resistance ratings, stain resistance, and abrasion resistance all contribute to long-term value. Each design collection undergoes mechanical testing to verify compliance with international standards.

Global Market Position of Sodiceram

Sodiceram has steadily expanded its footprint across international markets, leveraging export partnerships and distribution networks to reach a diverse customer base. Globalization has intensified competition in the ceramic sector, with manufacturers competing on price, innovation, and logistics efficiency. Strategic market entry requires understanding regional regulatory frameworks, import duties, and consumer preferences. The company’s ability to tailor product specifications to meet regional certification requirements has strengthened its international acceptance.

The table below outlines general factors influencing ceramic export performance across markets.

| Market Factor | Impact on Export Growth |

|---|---|

| Tariff Regulations | High |

| Logistics Infrastructure | Medium to High |

| Brand Recognition | High |

| Local Competition Intensity | High |

| Currency Stability | Medium |

Brand recognition plays a pivotal role in international competitiveness. By participating in global trade exhibitions and maintaining distributor partnerships, the organization has reinforced visibility in strategic markets.

Supply chain reliability further enhances its standing. Timely delivery, standardized packaging, and responsive customer service contribute to sustained distributor relationships.

Sustainability Strategy of Sodiceram

Sustainability has evolved from a secondary concern to a primary operational priority across manufacturing industries. Sodiceram integrates environmental responsibility into its long-term strategy by focusing on energy efficiency, waste reduction, and water recycling. Ceramic production requires significant water usage during material preparation and glazing. Modern recycling systems enable the reuse of process water, reducing freshwater consumption and minimizing discharge. This closed-loop approach lowers operational costs while supporting environmental compliance.

Waste management represents another critical dimension. Broken tiles and rejected pieces can be crushed and reintroduced into the production cycle as raw material components. This practice decreases landfill dependency and enhances material efficiency. Carbon emission reduction is addressed through kiln optimization and alternative fuel exploration. Transitioning toward lower-emission energy sources aligns operations with global environmental targets and regulatory expectations.

The sustainability framework can be summarized through measurable indicators.

| Sustainability Metric | Operational Objective |

|---|---|

| Water Recycling Rate | Above 80% |

| Energy Efficiency Ratio | Continuous Improvement |

| Waste Reutilization Level | High Internal Reprocessing |

| Emission Monitoring | Regulatory Compliance |

By embedding sustainability within strategic planning, the company demonstrates accountability to stakeholders and environmental standards.

Future Outlook for Sodiceram

The future outlook for Sodiceram reflects a combination of digital transformation, market diversification, and innovation-driven expansion. The ceramic industry continues to experience shifts driven by smart manufacturing, automation, and data analytics.

Industry 4.0 technologies enable predictive maintenance, production monitoring, and defect analysis through real-time data integration. By leveraging digital dashboards and sensor-based systems, manufacturers can reduce downtime and improve yield rates. E-commerce growth also influences the construction materials sector. Digital catalogs, virtual showroom experiences, and online order tracking systems are reshaping buyer interactions. Strengthening digital engagement will likely play a significant role in future expansion strategies.

Urbanization trends worldwide continue to drive demand for residential and commercial construction. Infrastructure projects, housing developments, and renovation markets provide consistent growth opportunities. By aligning production capacity with emerging demand regions, the organization can secure long-term growth. Research and development will remain central to competitiveness. Innovations in lightweight ceramic materials, antibacterial surfaces, and energy-efficient manufacturing processes may define the next generation of product offerings.

Economic fluctuations, however, require strategic resilience. Raw material price volatility, transportation costs, and currency exchange rates can influence profitability. Diversifying supplier networks and strengthening operational flexibility can mitigate such risks. As global construction standards evolve, compliance with environmental certifications and safety standards will become increasingly important. Proactive adaptation to regulatory frameworks ensures uninterrupted access to international markets.

Conclusion

Sodiceram stands as a reflection of how strategic vision, operational excellence, and sustainable practices can shape long-term success within the ceramic industry. From its foundational commitment to quality manufacturing to its evolving sustainability framework, the company demonstrates adaptability in a competitive global market. Manufacturing precision, design innovation, and export strategy collectively define its market presence. By integrating technological advancements with environmental responsibility, the organization positions itself for continued relevance in an increasingly dynamic industry.

Looking ahead, digital transformation, global urbanization, and sustainable production will likely influence strategic priorities. Companies that balance efficiency with environmental accountability will lead the next phase of industrial growth. Within this context, the brand’s structured approach to innovation and quality assurance provides a solid foundation for future expansion and continued global recognition .Through disciplined operations, market awareness, and forward-looking leadership, it remains aligned with the evolving demands of architects, distributors, developers, and consumers worldwide.